Cut costs and conserve energy in commercial kitchens

Understanding energy usage in commercial kitchens

Commercial kitchens are among the most energy intensive areas of a business, with equipment, lighting and HVAC systems consuming large amounts of power. Identifying key areas of energy consumption helps to implement more cost-effective solutions.

Smart kitchen design for energy efficiency

The layout of a kitchen is key to saving energy. Consider keeping fridges and freezers away from heat sources to cut cooling costs, and space them out for better air circulation. Strategically position vents and exhaust hoods to remove heat without taxing your HVAC (heating, ventilation, and air conditioning) system. By placing frequently used appliances within easy reach of each other, you can reduce movement and energy waste, keeping your kitchen running smoothly.

Lighting and HVAC: Optimising energy use beyond appliances

Did you know by switching to LED lighting you can reduce electricity usage by up to 80% (British Gas 2023). Pairing these with motion sensors to automatically turn off lights when areas are unoccupied such as dry stores and offices can improve energy savings even further. Additionally, dimmer switches allow lighting to be adapted depending on the need, helping to reduce electricity bills.

When it comes to HVAC systems, finding an optimal temperature is key to reducing energy consumption and cutting costs. Adjusting the temperature by just one degree can lead to significant savings without sacrificing comfort.

1. Be prepared

Think ahead! Plan meals for the week so you can ensure joints of meat and other food is fully defrosted in the fridge and ready to cook with. Also try and limit your time going in and out of fridges and freezers so they don’t need to work as hard to cool down again.

2. Staff training

Ensure your team has the knowledge and confidence to run a kitchen efficiently and implement energy saving principles. Our free E-learning platform, Caterer’s Campus, exclusively available to all Bidfood customers, offers modules covering kitchen efficiency, environmental awareness and much more.

On the topic of cost saving, on average, companies spend £1,590* per staff member annually on training and development. Caterer’s Campus saved our users 4.1 million* last year alone! And that’s not even counting the extra costs of certified training costs, travel or time out of the business.

*This is an average figure released by a government survey. More info on this can be found here.

3. Energy champions

Create a culture of energy saving in the team. Have “Energy champions” who are responsible for turning off lights, ovens and equipment when not in use and making sure that heating and hot water are set at the right temperature.

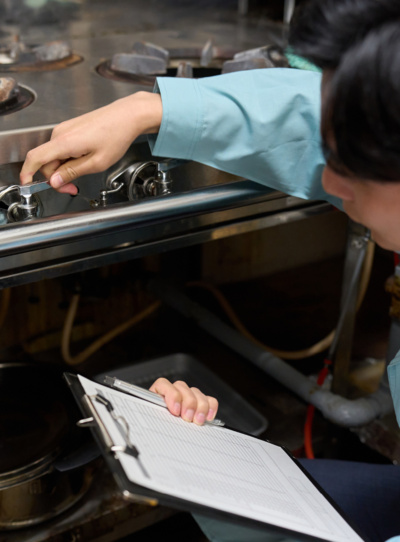

4. Provide a checklist

Implement energy-saving checklists in your kitchen to reinforce good habits. Our Food Development Chef, Paul Tunnicliffe, has shared his check list to help you find opportunities to save energy usage in your kitchen. Download our daily checklist here.

Conclusion and next steps: Creating an energy-efficient kitchen

By implementing these strategies, your commercial kitchen can significantly reduce energy costs and enhance operational efficiency. Start today by assessing your energy usage, training staff and exploring energy-saving equipment upgrades to build a more sustainable and profitable kitchen.

Visit our How to increase the profitability of your menu webpage to discover more tips and ideas to run a more efficient and profitable kitchen.

Energy efficiency in commercial kitchens

What are the best quick fixes for reducing energy waste?

Quick fixes include switching to LED lighting, turning off equipment when not in use, batching cooking where possible and avoiding overloading fridges/freezers.

How do I know if my kitchen is energy efficient?

Conducting an energy audit is the best way to assess your kitchen’s energy efficiency. An audit evaluates equipment usage, lighting, HVAC and insulation to identify inefficiencies.

What are the biggest energy drains in a commercial kitchen?

Major energy drains include ovens, fryers, fridges, freezers, dishwashers and HVAC systems. These appliances consume significant amounts of power when not properly maintained or optimised.

How can I calculate my kitchen's energy usage?

To calculate energy usage, track your electricity consumption through your utility bills or by using an energy monitoring system that measures appliance usage in real time.

How often should I service my kitchen equipment to keep it energy efficient?

Kitchen equipment should be serviced regularly, typically every 6-12 months, depending on usage, to maintain efficiency, prolong lifespan, and ensure optimal performance.

Does using energy-efficient appliances really make a big difference?

Yes, energy-efficient appliances can make a significant difference by lowering energy consumption, reducing operational costs and minimising environmental impact over time.

How can I train my staff to be more energy-conscious?

Educate staff on energy-saving practices, such as turning off equipment when not in use, keeping doors closed on ovens and fridges and practicing efficient cooking methods. Check out our eLearning platform, Caterer’s Campus to support your teams learning.

Lighting & HVAC efficiency

Is LED lighting worth the investment for my kitchen?

Yes, LED lighting is highly energy-efficient. The initial investment is quickly recouped through lower energy bills.

How can I optimise my ventilation system to save energy?

Regular maintenance, such as cleaning filters and ducts, adjusting airflow based on usage, and installing energy-efficient fans, can help reduce energy consumption while maintaining air quality.

Technology

What smart technologies can help my kitchen save energy?

Smart thermostats, energy monitoring systems and automated lighting can optimise energy use by adjusting settings based on real-time data.

How do energy monitoring systems work, and are they worth it?

Energy monitoring systems track energy consumption across different appliances, providing insights into usage patterns and identifying areas for improvement.

Can automating certain kitchen processes help reduce energy costs?

Yes, automation, such as temperature adjustments and scheduling, can reduce energy waste by ensuring equipment operates only when needed.